Pocket holes are a very simple, quick, and convenient way to join wood. In many cases, the holes can be placed in a way that they are invisible. Unlike with dowels, biscuits or dominos, it is not necessary to drill (and thus align) holes in both pieces. Only one piece is pre-drilled, and then screwed to the other piece.

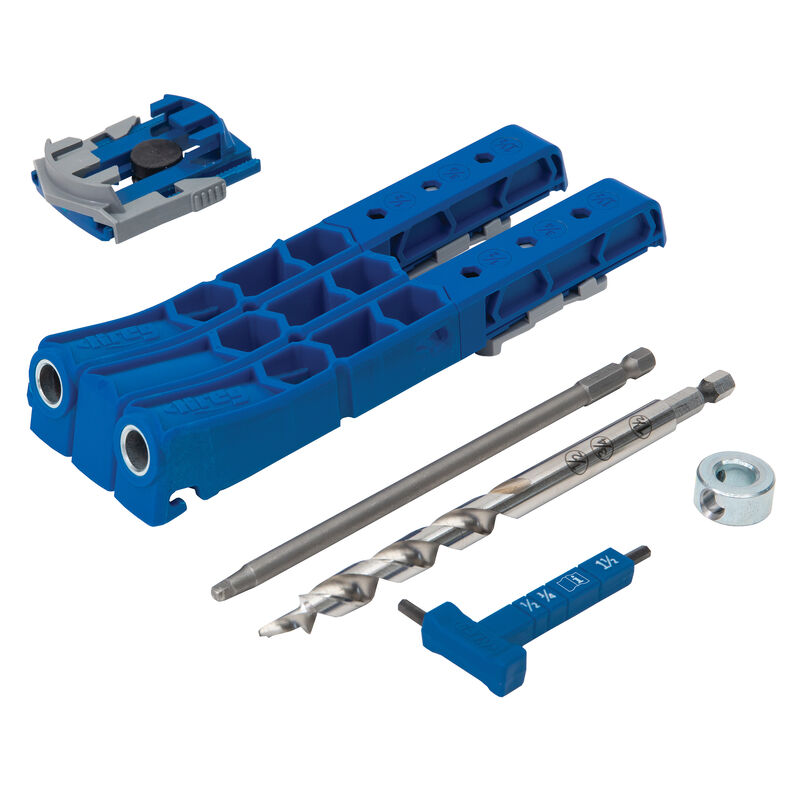

Kreg sells a number of different pocket hole jigs, from the very simple 310 to the K5. The latter is a sensible investment for daily use, but for my occasional use, I decided to go with the 320. It comes with a thickness gauge, the drill bit, and Kreg’s square-head screw bit. I would also definitely add one of Kreg’s quick-release clamps, as it is very difficult to drill accurately without clamping the jig to the workpiece. You should also get sufficient screws, I decided to go for the Pocket-Hole Screw Project Kit, which has screws for all board thicknesses (12mm/18mm/25mm, i.e. 1/2″, 3/4″, 1″) supported by the 320 jig.

Using the jig is very simple. You first set the jig for the board thickness, which can be measured with the included gauge. You then set the depth limiter on the drill bit to the same value. The jig is then clamped to the edge of the board, then you drill the hole(s). The 320 jig lets you drill two holes without re-clamping. With all holes drilled, you align the two pieces of wood as desired, insert a screw, then screw it in place.